Sensors & Measurement

As an end-to-end system provider, we can provide our in-house or third party sensors and connectivity to existing systems on board the vessel to increase the transparency and accuracy of the vessel performance management.

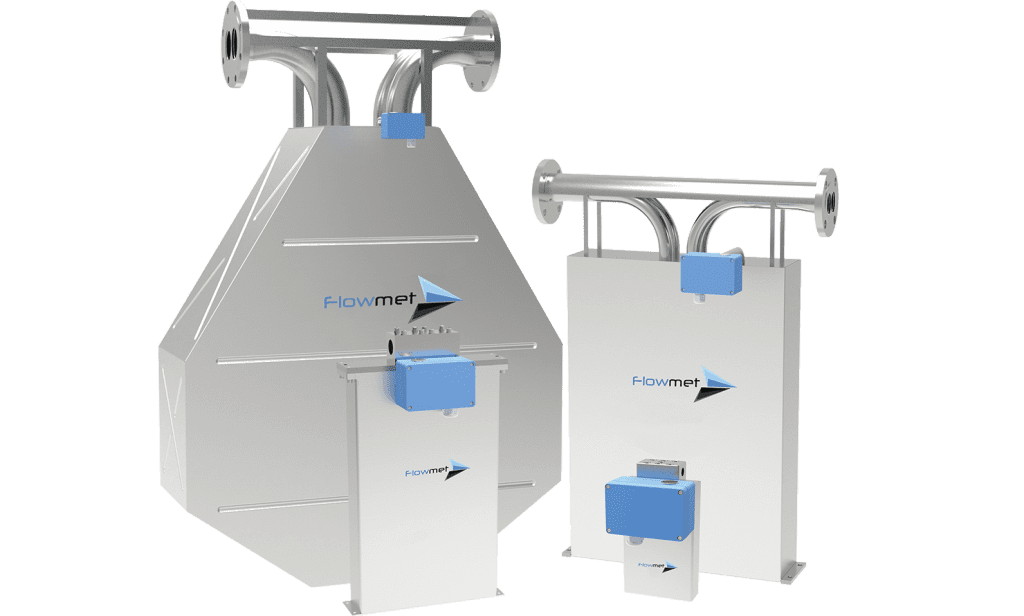

Flowmet™

Flowmet™ are Coriolis Mass Flow Meters that provides highly accurate measurement performance. Flowmet™ measures the inertial force created by the movement of fluid through the tubes. A swinging motion generated by the vibration of tubes in which the fluid flows and the tube twist or angle of deflection is measured and converted into a mass flow measurement. The flow meters are unaffected by flow profiles, concerns arising from changing temperature, viscosity, and pressure conditions are eliminated to deliver higher accuracy and reliability. Flowmet™ works across a wide range of flow rates and process conditions to significantly lower installation and operation costs.

Flowmet™ are perfectly designed for reliable and accurate measurements under challenging conditions, and it is the starting point of any kind of best possible vessel performance management.

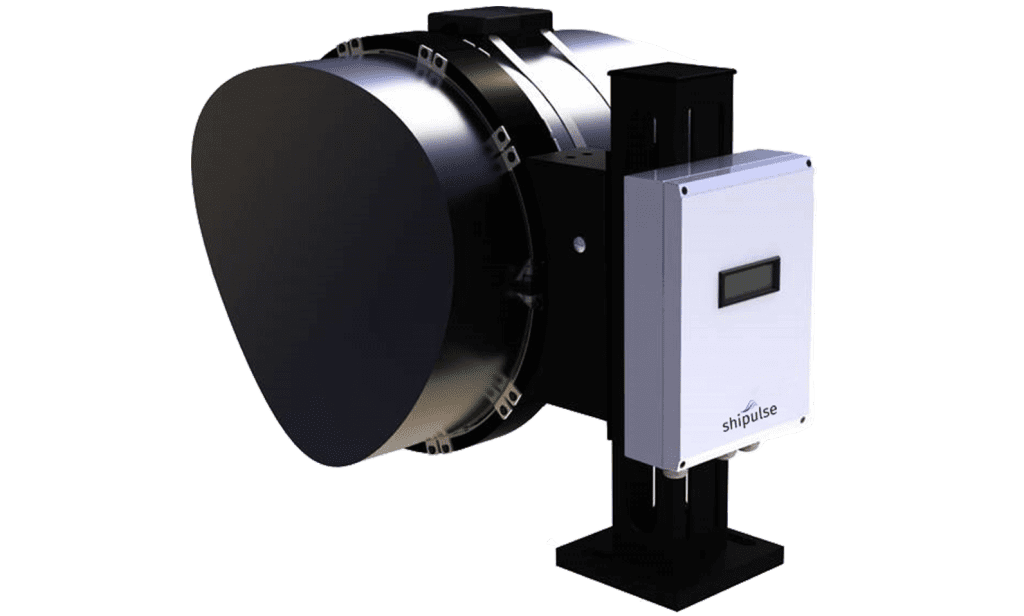

Torquemet

High fuel consumption can be caused by a variety of factors such as equipment issues, low-quality fuel, and bad weather. To identify the root cause of key inefficiencies, Torquemet torque meters measure and monitor key performance indicators from torque and power transferred from the main engines to the propellers such as Torque (Nm or kNm), Speed (rpm), Power (kW), Energy (kWh or Joules) SFOC (g/kWh), and Kw per mile.

Torquemet measures the torque on a rotating system. The torque meter installed is fitted with either an optical sensor or a strain gauge to measure the rotary and reaction torque on the shaft. The torque meter is also equipped with a tachometer to measure shaft speed. The shaft torque and shaft speed data are used to measure the power transferred from the engines to the propellers.

The data output from the torque meter is logged on the data acquisition system to allow data integration with different ship systems. By combining this data with the fuel consumption monitoring system, further useful information, such as understanding the engine efficiency is generated.

Emissions Measurement: CO, CO2, SO2, NO, NO2 & CH4

Our sensor provides all-in-one emissions analyser for the marine applications. By continuously scanning the infrared spectrum up to 14µm the analyser can identify gas composition or any specific trace gas with a fingerprint in the infrared. The technology is inherently robust against drift and allows for auto calibration. The Fabry-Perot filter offers exceptional selectivity allowing accurate determination of the components and levels in the gas mixture. The measurement principle does not require time for separation of the gas components and needs only a small amount of gas providing quick response time. The analyser does not require any consumables such as carrier and calibration gases. The sample gas is analysed directly as it flows through the optical path within the analyser. This saves the user from the cost, space, logistics and HSE risks.

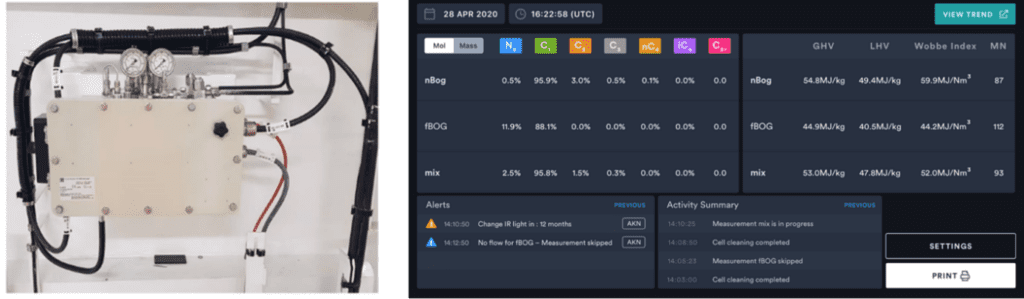

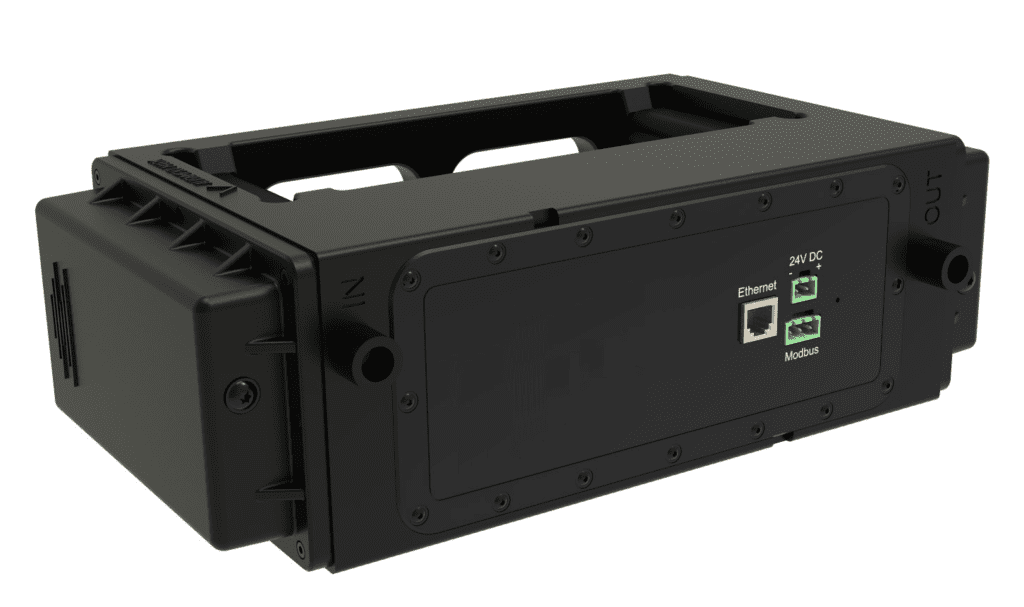

Gas analyser

Gmet, our Natural Gas analyser provides clear breakdown of gas composition, such as methane, ethane, propane, Iso-Butane, N-Butane and C5 total. It is designed for quick installation and usability on-board vessels. The compact design is not only suitable for use in hazardous areas, it also does not have moving parts, making it a robust solution that requires very minimum level of maintenance.